,,You ask me what were the secret forces which sustained me during my long fasts. Well, it was my unshakeable faith in God, my simple and frugal lifestyle and the Aloe, whose benefits I discovered upon my arrival in South Africa at the end of the nineteenth century.’’

Mahatma Ghandi (1869-1948)

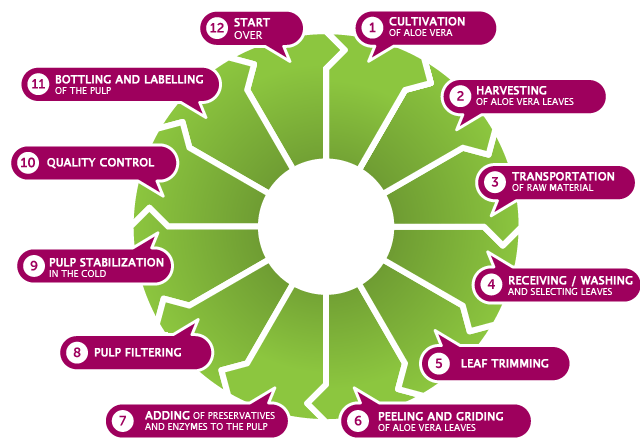

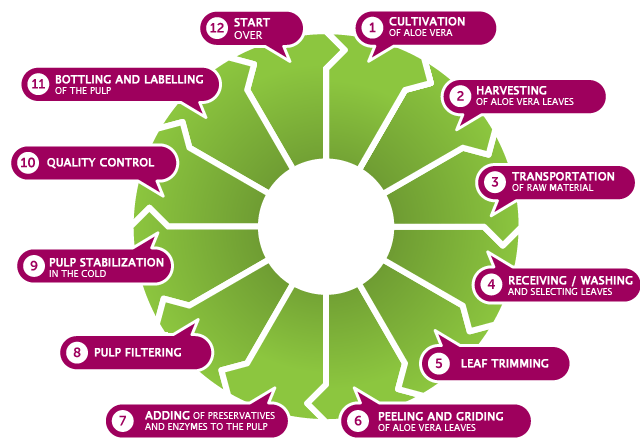

The preparation process

Several researches have concluded that the properties of aloe vera are not contained in a single component but in the combination of its elements. For that reason, in Lanzaloe we take absolute care of every part of the production process. There is constant supervision on its quality so as to guarantee that the pulp we extract from the aloe plant to prepare our products preserves all its benefits.

1.Cultivation of the plant

Aloe Vera is cultivated from its off shoots: baby plants that sprout around the stem of adult plants and are plucked from their roots to be transplanted. Aloe vera is a strong plant, but there are certain factors that might boost its growing. It is better grown on sandy soil, with a thirty-degree inclination. Should not be exposed to humidity since it can cause fungi to appear.

2. Harvesting of Aloe Vera leaves

It is necessary to wait for the plant to be adult in order to harvest its leaves from which pulp is extracted. Leaves should be cut as close as possible to the stem and all leaves that may be dry or torn should be thrown away.

3. Transportation of raw material to the processing plant

While part of the staff is involved in the cutting of leaves, another part takes those leaves to the plant for the immediate extraction of the pulp. That way we will guarantee that all properties of aloe are preserved during the process.

4. Receiving/washing and selecting leaves at the plant

When leaves reach the plant they are plunged into a plastic tank full of water and cleansing products. To guarantee total disinfection and cleanliness leaves are brushed. Finally, the leaves are put on a conbveyor belt wwhere they are washed with pressurized water system.

5. Leaf Trimming

The tip and sides of each leaf are trimmed and leaves are then put into special tanks containing a mixture of water and cleansing products. At this stage any possibility of contamination should be avoided by keeping all tools properly sterilized. Remains from the leaves resulting from this process will be later used as fertilizer in the fields.

6. Peeling and grinding of Aloe Vera leaves

Once trimmed, leaves are put into a peeler where the outer parts of them are separated from the inner part: pulp. The same peeler grinds the pulp to extract the juice. It is then sent to a tank through a coil that lowers its temperature while transporting it.

7. Adding of preservatives and enzymes to the pulp

The first amount of preservatives that will keep the not-yet-filtered pulp from oxidation, and the enzymes that help in the filtering process are added.

8. Pulp filtering

The pulp resulting from the previous stage is filtered in order to make it ready to be used.

9. Pulp stabilization in the cold

The last amount of preservatives and antioxidants are added aand, then, stirred inside a tank provided with a stirrer.

10. Quality Control

Two samples of aloe vera pulp are taken. One sample is examined to control its pH and density whereas the other one is sent to an outside laboratory to have an exhaustive microbiological examination. Once the perfect conditions of the pulp are confirmed, it is separated into two parts. One of them will be used to prepare different products (gel, soaps, shampoo, creams, …). The other one will be bottled and labelled.

11. Bottling and labelling of the pulp

Before starting to bottle the pulp, we should check that all due hygienic standards are met. Once confirmed, we bottle the pulp, seal the containers and label them.